We think the future is important

Sustainability

At Ackurat, we work actively with sustainability, big and small. From the materials we use in our products to the recycling in the lunch room. We may not be able to do everything overnight, but if we always keep sustainability in mind, we can make the world a little better every day. Join us on our sustainability journey.

Hållbara material

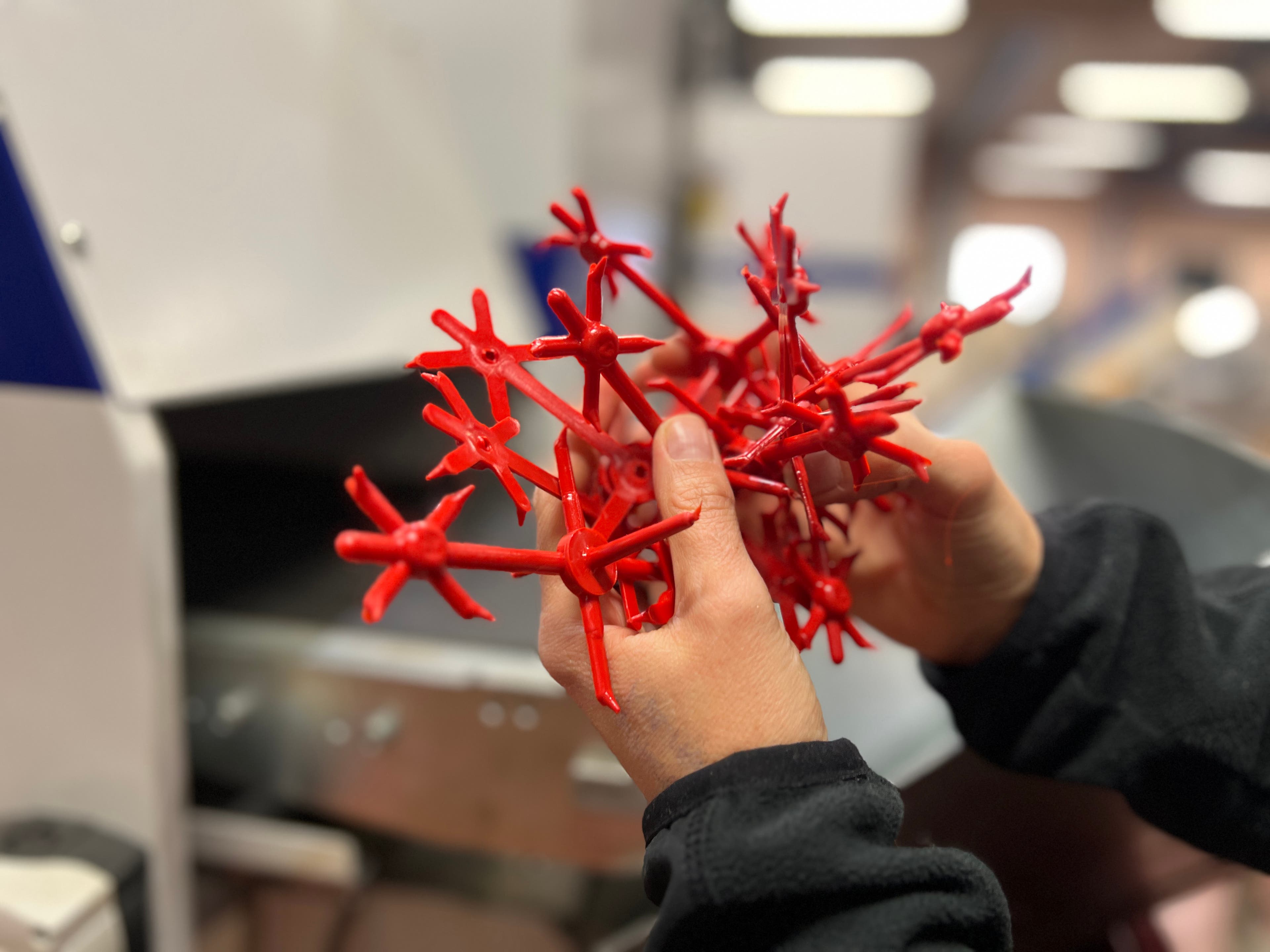

Right now, we are working on testing new materials in recycled plastics. The plan is that we, to the extent we can, will replace plastics from fossil sources, so-called virgin plastics, with recycled plastics in our products. We already have items that contain recycled materials, e.g. our glide caps XCF-004 with 50% rPET and our new stacking bumpers SPSC-DK01 with recycled LD-PE. And there will be more.

Look out for this symbol, which means that the product contains recycled materials.

The materials we work with are of course available as a choice for customised parts.

Product development

When we develop new products, we have renovation as a criterion. We want to develop standard items that are easy to replace and easy to find when it's time to renovate furniture. Our new PIN-CH® series is an example of just that. It is available for both wood and round tubes of different dimensions. In addition, the name and size are written on the product in case you forget. Another criterion when developing new products is to choose a recycled material and to make the product recyclable to close the circle. We haven't reached all the way yet, but we're are well on our way.

Waste management

In recent years, we have had as a goal to reduce our combustible waste by at least 5% a year. This makes you think. We have become better at reintroducing residual material back into the process so that there is less production waste. We have put in recycling bins in the lunch room so that materials that can be recycled do not end up in the general waste. We have simplified packaging recycling in the production area so that plastic is recycled instead of ending up in the waste container. We streamline processes and plan, for example, so that products with the same material run on the same machine so we do not have to change materials as often. All this has resulted in us reducing the waste in the wastecontainer so much that it only needs to be emptied every two weeks instead of every week. And we can get better.

Every little helps

- what we've done so far

Renewable energy

In our production facility in Lammhult, we use 100% renewable electricity from Bixia.

Charging point

At our car park in Lammhult there is an charging point so that employees can charge their cars at work.

Recycling

In our lunch room, we have bins for paper, plastics, metal, glass, newspapers, food waste, batteries, light bulbs, deposit cans and bottles, and general waste to make it easy to sort our rubbish.

Recycling – transparent bags

With simple means, we try to find solutions to facilitate recycling in practice. For example, having transparent plastic bags so that you can see the contents, allows you to clearly see where to put different types of packaging.

Reusing boxes

If the boxes we receive deliveries in are in good condition, there is no reason to squeeze them together and send them for recycling. We use them again and pass them on instead.

Creative reuse

of products with Re:Play

We find it inspiring to collaborate with Re:Play and support their valuable work. Together, we work to reuse discarded products and residual materials.

Re:Play was born out of the realisation of our overexploitation of the planet's resources. To create real change and get away from the throw-away society, business models must also be adapted. The ambition is to help customers transition to a circular economy based on function rather than ownership and to maximize the use of already existing resources.

At the preschools, we create an environment with recycled materials that benefit the children's creativity and development. By working with industry to save materials from waste, local production and shorter transport distances, we reduce the environmental impact. It’s a win-win situation.