How should the product look and feel?

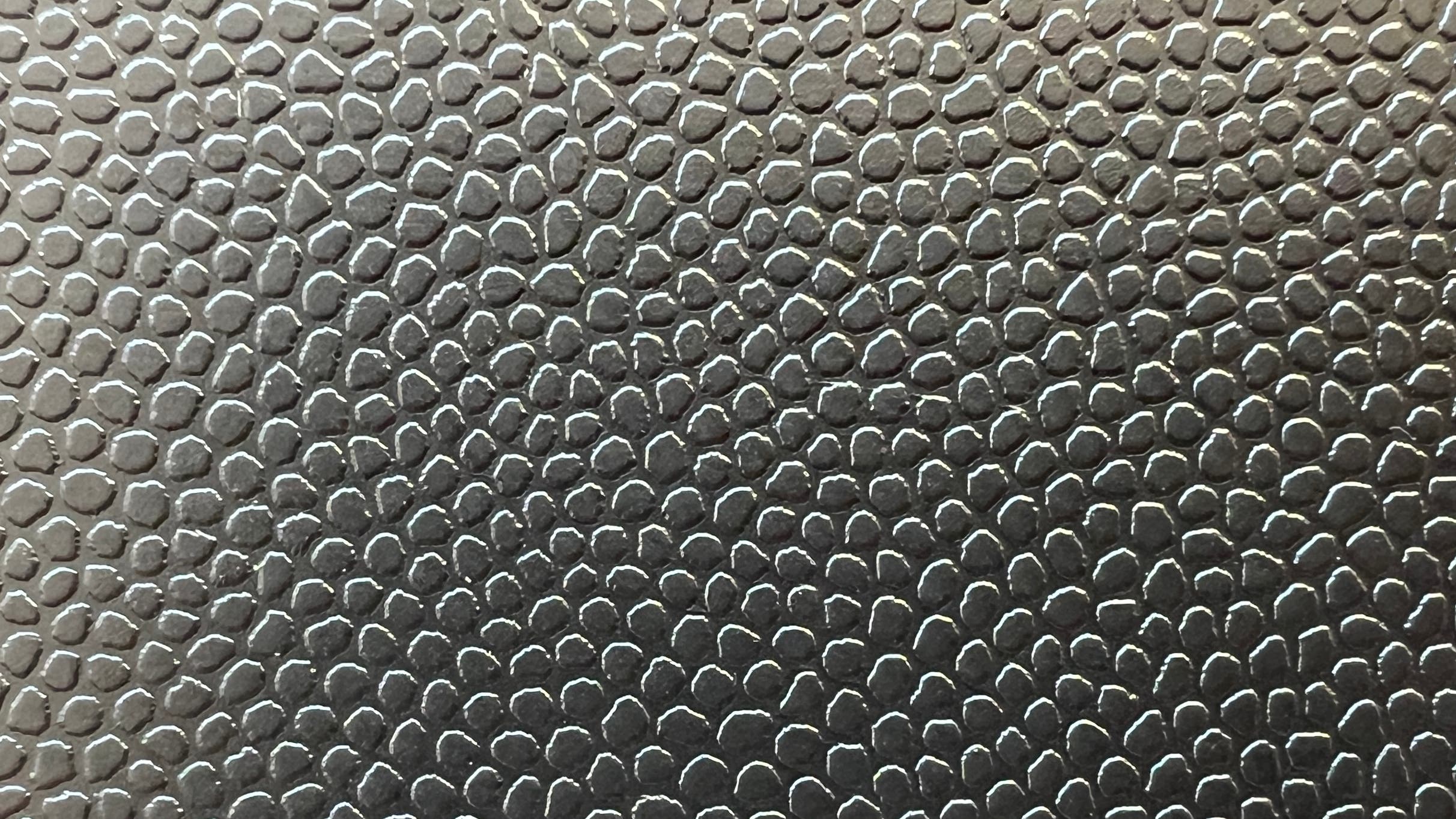

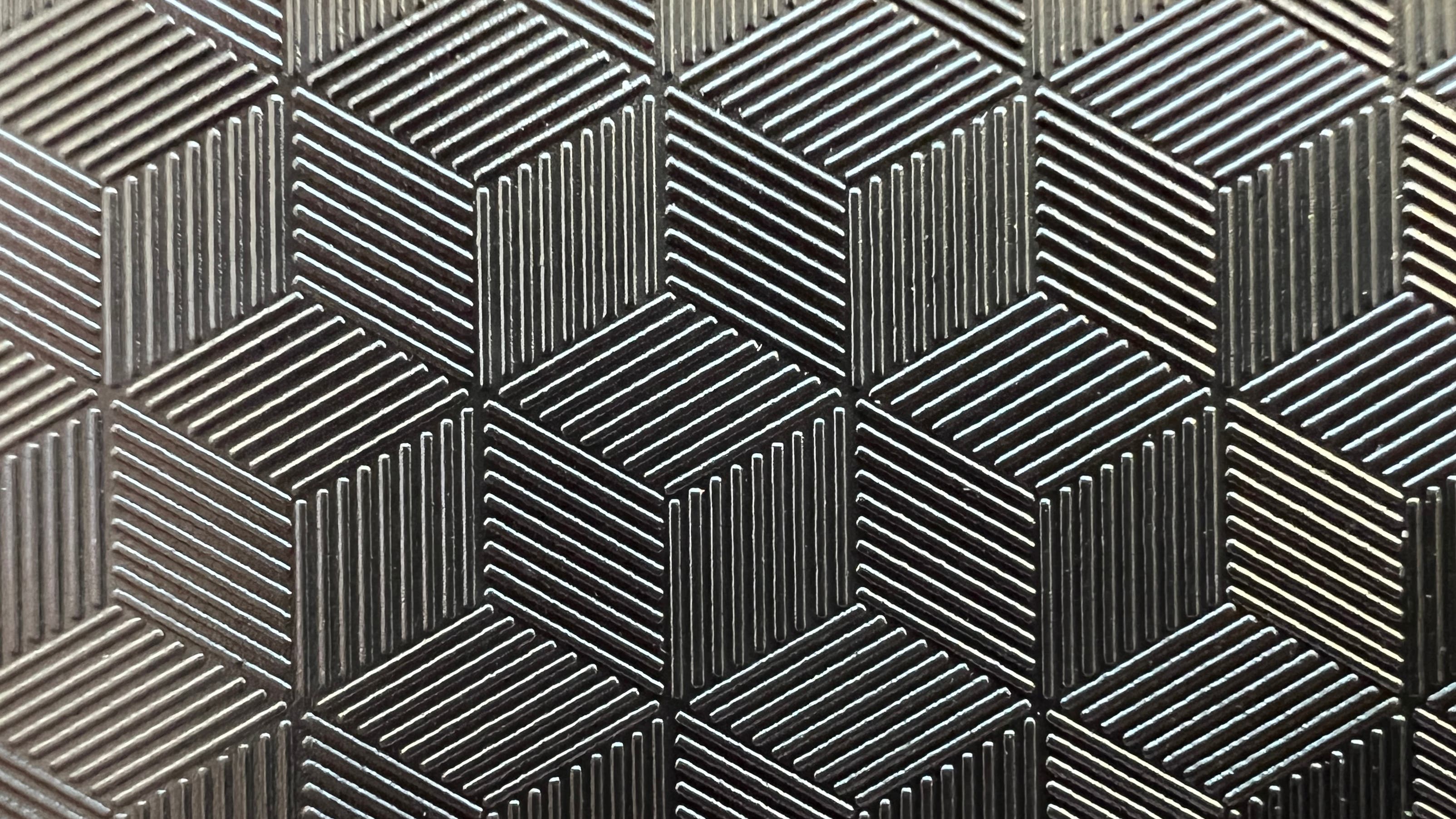

Surface finish and patterns

for plastic surfaces

There are many options when it comes to surface finish for injection molded plastic parts.

The possibilities are almost endless.

Ra and VDI for

function and design

Ra and VDI are two surface finish structures. Ra measures the peaks and valleys of the microscopic grains on the surface texture, while the international standard VDI indicates the texture for matte surfaces. Both indicate how rough or smooth the surface will feel.

Visually, you may want to imitate a material or perhaps prevent glare. Ultimately, it should fit both the product design and be functional.

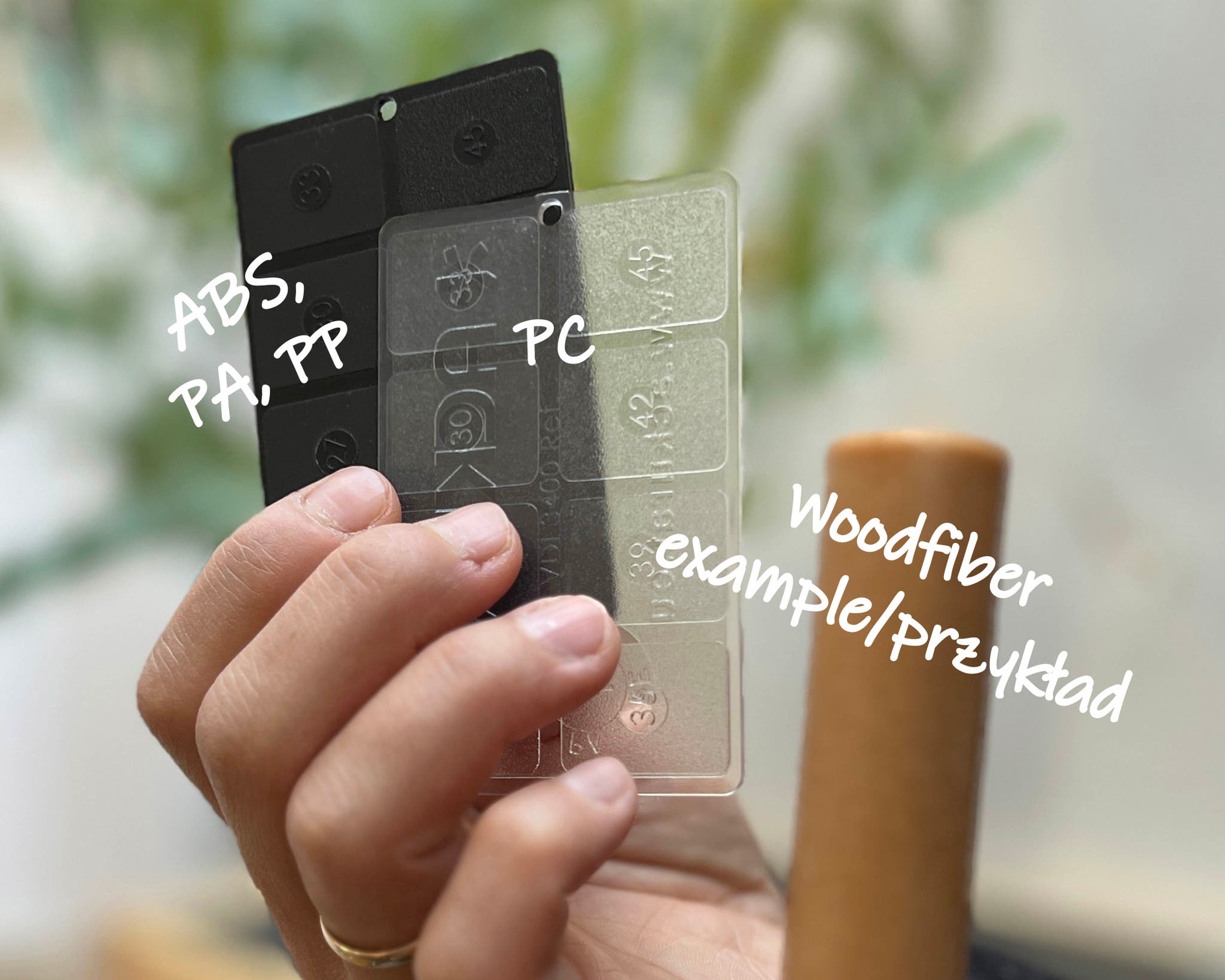

Do you need a VDI sample plate?

If you are considering the surface finish for your product and need to see them in reality, contact one of our product specialists, and they will send you a sample plate. The plates are available in materials: ABS, PA, PC (clear), PP, and Woodfiber.

Here you can see examples of different patterns that can be used on injection molded plastic parts

Want to know more about plastic?

Order the book “Worth Knowing About Plastic” from Polymercentrum.

Available in English.

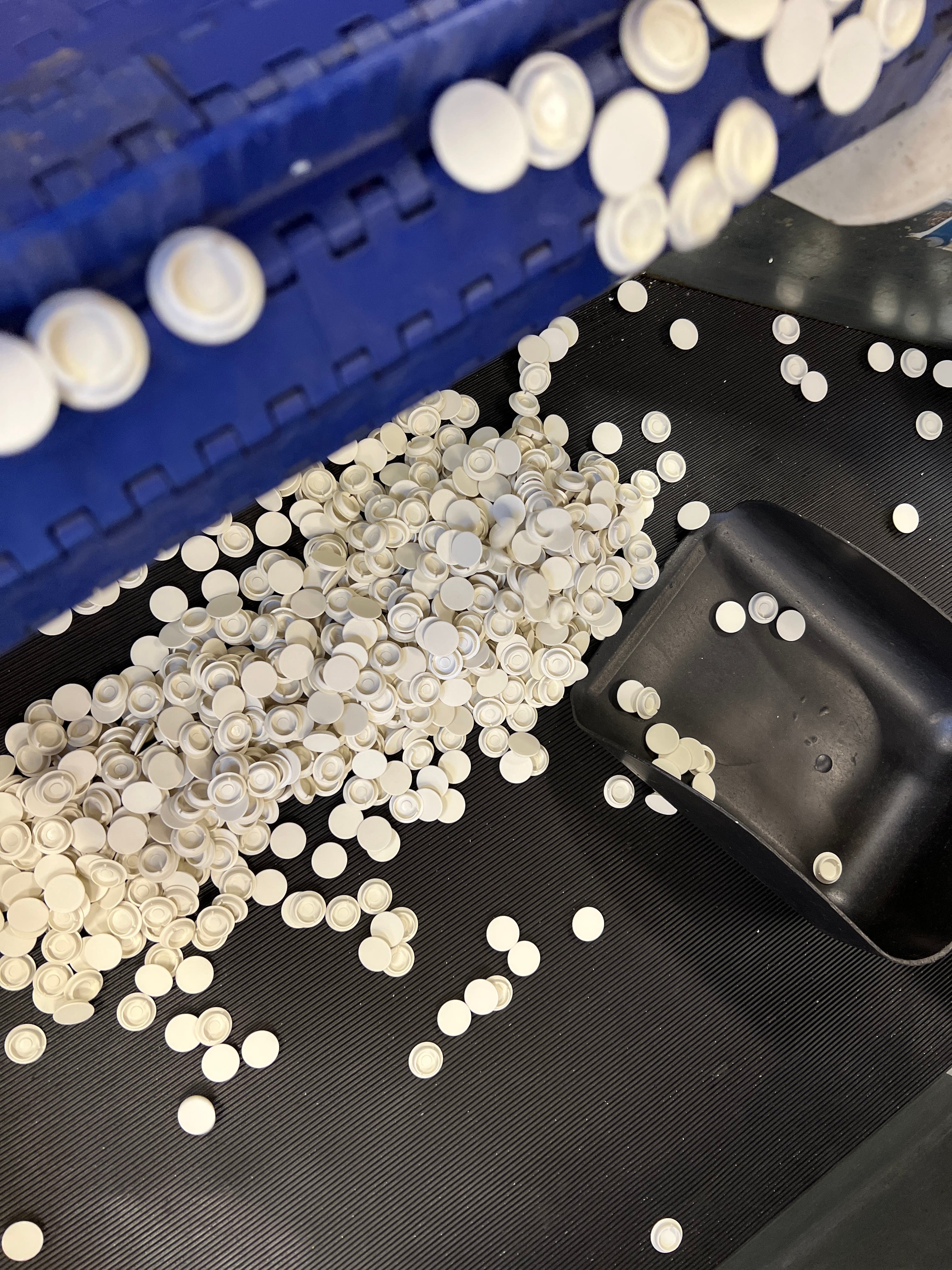

Plastic materials for injection molded plastic parts

When it comes to injection molded plastic, the choice of plastic material is crucial for the result. With the right material, you get a longer product lifespan, increased strength, and better resistance to chemicals. If you need to discuss plastic materials, please contact our product development department.

Injection molding - how it works

The production of injection moulded plastic parts requires precisely adjusted machines where our knowledge of the plastic’s properties is very important. Read about how injection moulding works.