The world demands that we think circularly

Andreas Mattisson, previously at Lammhults Möbel, Sweden.

Read what he had to say about us

Existing products can be

further developed

ANDREAS MATTISSON - RANGE AND PRODUCT DEVELOPMENT MANAGER | For Andreas Mattisson, who previously was Range and Product Development Manager at Lammhults Möbler, product development is about much more than developing new products. Today you can find him at EFG & SAVO. He has been working with product development since 2005 when he finished his education at the University of Växjö. Much of the work has been interesting new development, but he also sees great potential in developing products that already exist. By this, he doesn't mean relaunching old products, but rather developing further with the old products as a foundation.

Too little focus is placed on what already exists. This can often be developed into something even better. In the light of the global changes we face, the focus must be on the existing , making it more circular.

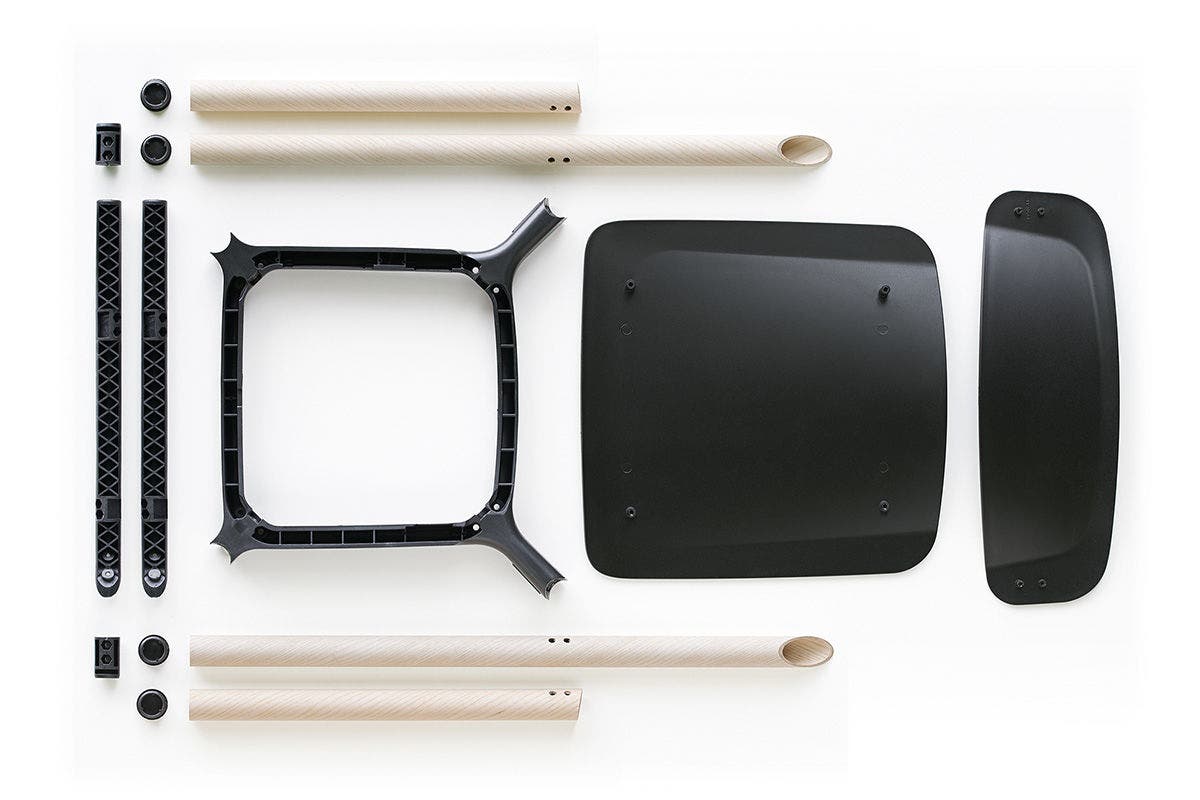

During his time at Lammhults Möbel, the views aligned that product development is very important, both new development and further development of existing range. At Lammhults Möbel, the goal is the longest possible life cycle, and this requires timeless design of the highest quality. Lammhults works with three core values: Long-term perspective, relevant innovation, and attractive identity.

Lammhults works to reduce resource consumption and decrease its environmental impact, and therefore they develop and produce products from materials that can be recycled as material or energy. They strive to prevent pollution in all their business processes and work to successfully reduce environmental impact and climate footprint in their production facilities.

Andreas on plastic materials

For me, sustainability is the most important issue in all decisions, but I think many discussions on the subject are skewed. Among other things, I'm skeptical about mixing foreign substances into materials and believe that materials should be kept pure to benefit their recycling. Woodfiber is an example I'm skeptical about as the addition of a foreign material to the plastic, in this case wood, destroys the material's recyclability.

We at Ackurat regularly visit the Lammhults company in the village of Lammhult (southern Sweden). They also have a login on Ackurat's website where, in addition to all standard products, they can see the company's prices, Ackurat's stock levels, Lammhults' own special products, and order history.

Andreas about Ackurat

The best thing is that Ackurat has niche expertise in the furniture industry. They therefore monitor relevant material development and can offer expertise on which material should be used where. The competence of a niche company is always higher than a company that isn't specialized; the development is more focused and thus supports our development in a better way.

Thanks to having their own tool department, they are also quick with special products and can therefore often offer very advantageous tool prices for smaller details. Project-wise, it's one of the most punctual partners we have. An improvement opportunity for Ackurat, in collaboration with Lammhults, would be to offer injection molding of slightly larger details and to provide a better range of recycled base materials.

Simon Pengelly - Pengelly Design Ltd, United Kingdom

Lauri Link - Standard AS, Estonia

Elena Zuccolo - Braida Srl, Italy

Hee Welling - Hee Welling Studio, Denmark

Armin Nurkic - Ingrat, Bosnia and Herzegovina

Tadas Morozas - UAB Vildeta, Lithuania

Rebecca Sykes - New Design Group, United Kingdom

Sławomir Miszczak - Nowy Styl Group, Poland

Vincent Dejonghe - Mobitec Systems SA, Belgium